三刀多功能数控切割机说明书

发布时间:2021-05-14 15:48 作者:易朗科技 浏览次数:

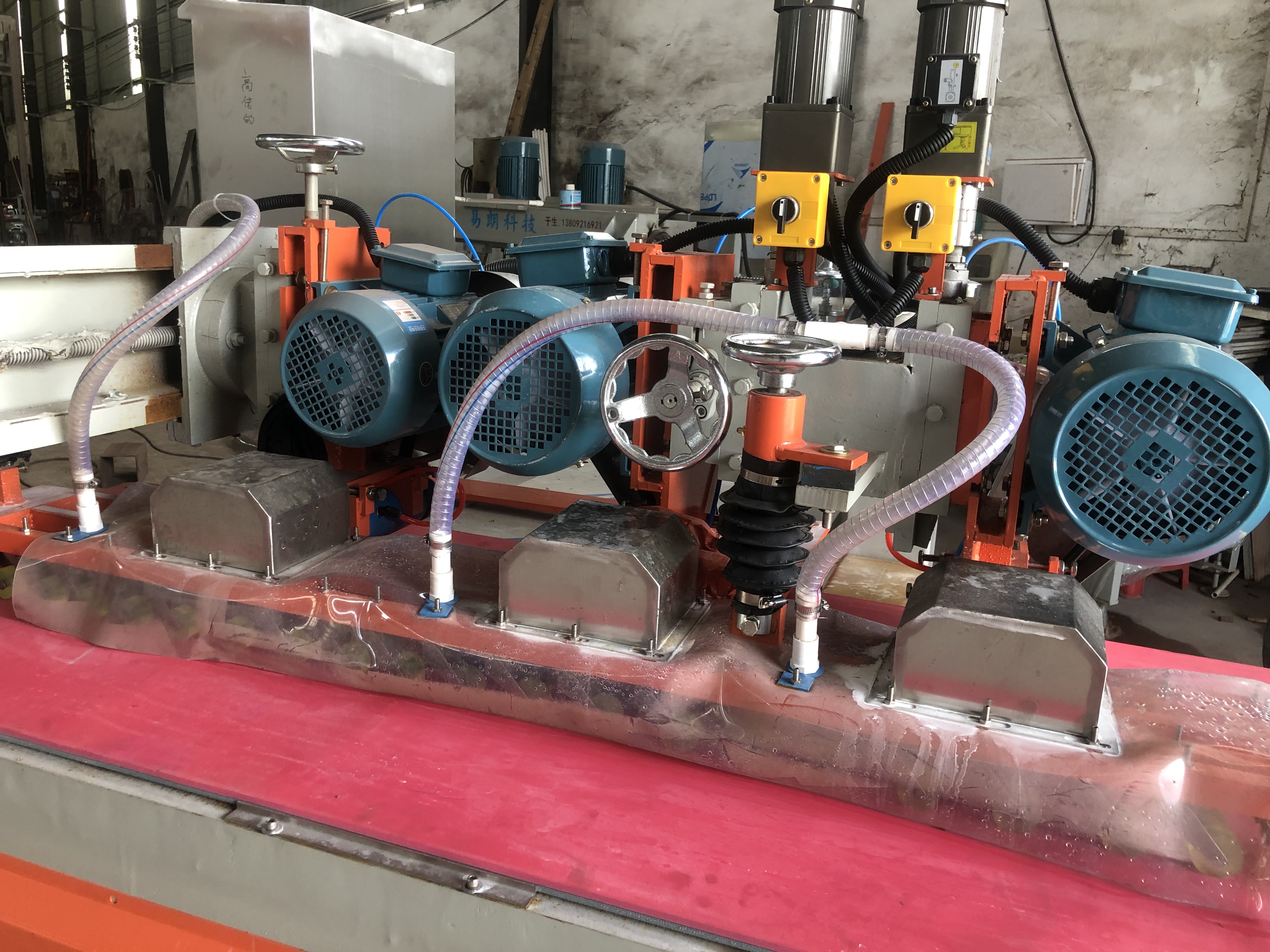

三刀多功能数控切割机说明书three head multifunction CNC cutting machine Instruction Manual

一、该机可用于一开二及多规格尺寸切割,一开二采用数控调节尺寸8秒内可调出所需的任何尺寸降低人工成本,还可以圆边,开槽,45度切割,用户在使用设备前,务必详细阅读、并理解本说明书的内容,以免因操作或维护不当,导致故障发生。如有不详之处,请向我公司咨询。The machine can be used for cutting two sizes and multi-specifications. The size of the first two can be adjusted by numerical control within 8 seconds to reduce the labor cost. It can also be edge, slotted, 45-degree cutting, before users use the equipment, be sure to read and understand the contents of this manual, so as to avoid improper operation or maintenance, resulting in failure. If there is any unknown, please consult our company.

二、规格及技术参数Specifications and technical parameters

1、机型

二、规格及技术参数Specifications and technical parameters

1、机型Model

1200型

2、总功率total power

12.1Kw

3、外型尺寸external size

2600X2200X1700

三、安装与调试Installation and debugging

1、安装前应检查各部件是否完好无缺,水、电、气路均应送至施工地段。 before the installation should check whether the components are intact, water, electricity, gas should be sent to the construction site

(1)

接通水、电、气路。connecting water, electricity and gas channels

(2)

启动空运转,运转正常后等待调试。start air operation, wait for debugging after normal operation.

四、操作

四、操作Operation

1、开机前的准备 before starting

(1)开机前,先检查各连接部位是否牢固,无极变速器内润滑油是否充足,传动皮带的松紧是否适度。before starting, check the connection parts are solid, whether there is enough lubricant in the CVT, whether the transmission belt is suitable.

(2)检查转动是否灵活;检查各转动、滑动部位是否涂满黄油,有无生锈。 check whether the rotation is flexible; check whether the rotation, sliding parts are covered with butter, there is no rust.

(3)启动各电机,运转时是否有异常响声。start each motor, whether there is abnormal noise when running.

(4)开通水源。opening up water sources.

2、开机Power on

1.

用手按ESC,文本上就会显示佛山市易朗科技有限公司 Press ESC with your hand and the text will display Foshan Elong Technology Co. , Ltd.

2.

用手按ENT,文本上就会显示设定距离,实际距离Press ENT with your hand and the text will show the set distance, the actual distance

3.

用手按SET,文本就会显示设定,然后按CLR,就会显示0.00,最后就输入你要切割砖的尺寸,如300X600,就输入数字3 0 0 文本就会显示300.0,再按确定键ENT,再按+/-,挡尺会自动到300.0mm的尺寸Press SET with your hand, the text will display settings, then CLR, then 0.00, and finally enter the size of the brick you want to cut, such as 300X600, enter the number 300, the text will display 300.0, then press ok, then +/-, the gauge will automatically reach 300.0 mm size

4.

如果切割出来的尺寸不是300.0mm的尺寸,是299.0的尺寸,这个时候就需要校正尺寸,按数字1显示屏会显示实际距离300.0mm,然后按SET,再按CLR,这时会显示实际距离0.00,最后按299.0mm,再按ENT,在按数字9,就把300.0mm校正为299.0mm了If the size cut out is not 300.0 mm size, is 299.0 size, this time need to correct the size, press the number 1 display will show the actual distance 300.0 mm, then press SET, then press CLR, this will show the actual distance 0.00, finally Press 299.0 mm, press ENT again, press 9 again, correct 300.0 mm to 299.0 mm

5.

在按ESC,按ENT,就会显示设定距离299.0mm,实距距离299.0mm,这时再按SET,会显示设定距离299.0mm,再按CLR会显示0.0mm,最后输入你要的300.0mm,再按ENT就OK了Press ESC, ENT, it will show the SET distance 299.0 mm, real distance 299.0 mm, then press SET, it will show the SET distance 299.0 mm, then press CLR will show 0.0 mm, finally enter your 300.0 mm, then press ENT OK

6.

功能介绍 Function description

功能一Function 1

:可对瓷砖进行切割The Ceramic Tile can be cut function

功能二Function 2

:可对瓷砖进行45度切割,45度倒角The ceramic tile can be cut 45 degrees, 45 degrees Chamfer function

功能三Function 3

:可对瓷砖进行磨1/4圆The ceramic tile can be ground 1/4 circle function

功能四Function 4

:可对瓷砖进行开槽,最多4道槽,5-6mm宽 it can cut the ceramic tile 4 slots, up to 4 slots, 5-6 mm wide

功能一使用方法如下:Function 1 the method of use is as follows:

将切割片固定在安装切割片的位置上有三把刀,第一把装树脂开槽片,轻轻开掉瓷砖表面釉面防止崩边,第二三把刀进行切断,注意三把刀需要在同一条直线上。The cutting piece is fixed at the position where the cutting piece is installed. There are three knives. The first knife is fitted with a resin slotting piece, and the glazed surface of the ceramic tile is gently opened to prevent the edge from collapsing. The second and third knives are used for cutting, note that the three knives need to be in a straight line.

功能二使用方法如下:Function 2 uses the method as follows:

把第一把刀旋转成45度,使刀片挨紧皮带表面,把需要加工的瓷砖调整到想切割的位置进行45度切割,如需倒角,把切割片换成倒角轮即可。the first knife rotation into 45 degrees, so that the blade close to the belt surface, the need to be processed tile adjustment to want to cut the position of 45 degrees cut, if need Chamfer, cut into the chamfer wheel can be.

功能三使用方法如下:Function 3 uses the method as follows:

把圆角轮固定在安装圆角轮处锁紧,然后把圆角轮降低到合适位置,并把瓷砖调整到想要磨削的位置。The round angle wheel fixed in the installation of round angle wheel locking, and then reduce the round angle wheel to a suitable position, and adjust the ceramic tile to the desired grinding position.

功能四使用方法:

功能四使用方法:Function 4 use method:

拿出随机配的4片隔套,跟先装一片到安装切割片处如图④,再装一片开槽片,然后再装一片隔套,再装开槽片。。。。。。,装完第四片后用螺母锁紧,然后调整你要开槽的瓷砖位置进行开槽take out the 4 pieces of partition set randomly, and install one piece to install the cutting piece as figure 4, then install a slotted piece, then install another piece of partition set, then install slotted piece. . . . . After the fourth piece is installed, lock it with a nut, then adjust the position of the tile you want to slotted

3、关机shutdown

(1)待全部砖走完后,依次关闭各电机;也可按下急停按钮联动开机。 after all the bricks to go, turn off the motor; can also press the emergency stop button linkage start.

4、注意事项Note

(1)出现意外情况应立即按下急停按钮,排除故障后重新开机。in case of accident, press the emergency stop button immediately and restart the machine after troubleshooting.

(2)机器在运动时应勤俭查、多观察,及时了解各电机发热情况,对严重发热的电机应停机查明原因,排除故障后方能开机。 the machine should be diligent and thrifty in the movement, more observation, timely understanding of the heat of the motor, the serious heat of the motor should be found out the cause of the shutdown, troubleshooting before starting.

(3)各无极变速器应在工作状态下调节,禁止停机状态调节。each stepless transmission shall be regulated under working condition and shall not be regulated under shutdown condition.

五、维护与保养 maintenance and Maintenance

1、每工作8小时后,应清洁机身污垢,清除破碎砖片,清扫工作场地,疏理排水沟,冲洗输送带内外面。冲洗时,应避免电机、电控制柜、电眼等溅水;并应断开电源后冲洗。 each work 8 hours, should clean the body dirt, remove broken brick, clean the workplace, drainage ditch, washing conveyor belt inside and outside. When flushing, should avoid motor, electric control cabinet, electric eye and so on splash water; and should disconnect power after flushing.

2、每工作一周后,应检查各紧固件、旋转件是否松动、输送带的张紧程度、机器的磨损以及各旋转件的润滑等情况。each work week, should check the fasteners, rotating parts whether loose, conveyor belt tension, machine wear and lubrication of the rotating parts and so on.

3、定期按要求进行润滑regularly according to the requirements of Lubrication

4、每工作一个月后,应检查输送带的张紧情况,还应检查输送带和导向导轨、轴承的磨损情况,如有不符,应予调整。after each month of work, should check the conveyor belt tension, should also check the conveyor belt and guide rail, bearing wear, if there is no match, should be adjusted.

5、每工作6个月后,除按上述各项检查外,还应规定换油,进行润滑工作。each work after 6 months, in addition to the inspection in accordance with the above, should also provide for oil change, lubrication work.

6、每工作一年后,要进行一次大维修,对轴承、密封件、输送带、导轨等作必要的检测、修理或更换;并按要求进行调整,恢复机器的工作状况。 after each year of work, to carry out a major maintenance, bearings, seals, conveyor belt, guide rail, etc. for the necessary testing, repair or replacement; and according to the requirements of adjustment to restore the working conditions of the machine.

新闻资讯

新闻资讯 公司新闻

公司新闻